Large manufacturers in the industry choose HUANUO; high standard manufacturing, to meet the stringent technical requirements.

PRODUCTProduct classification

Business consulting

![]()

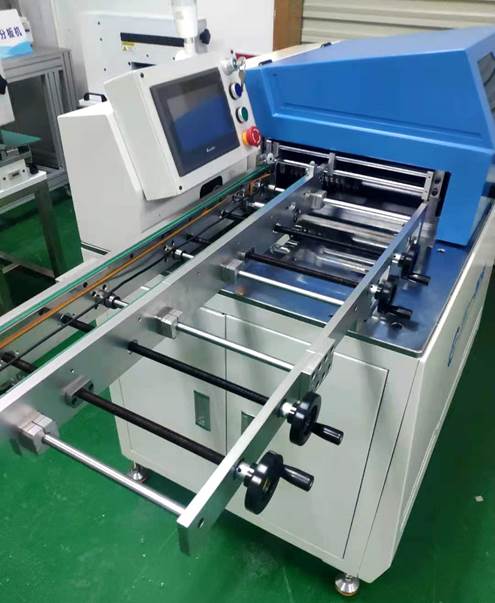

The HN-530 three-group multi-group multi-knife splitter can divide the board at one time and can be connected to the upper and lower board machines to realize unmanned operation. Not only the installation is convenient, the operation setting is also simpl

The HN-530 three-group multi-group multi-knife splitter can divide the board at one time and can be connected to the upper and lower board machines to realize unmanned operation. Not only the installation is convenient, the operation setting is also simple, which can save multiple employees, save time and effort. It occupies a small space and saves work time to the maximum.

1. Multi-group multi-knife splitting machine, according to the customer's 10 pieces of board, it needs to be equipped with three groups of 66 blades in total, and customized width gaskets.

2. The safety door has a magnetic protection switch, and the mechanical transmission gear has a protection cover.

3. The equipment is equipped with an automatic counting function, and the power supply of the equipment is controlled by an independent switch, which is convenient for timely processing.

4. After cutting, the waste board will directly fall off the belt line after cutting.

5. Equipment standard SMEEMA interface, rail transmission height: 920±30 Equipment voltage: 220v

6, blade material imported high-speed steel blade life 100,000 times

7. All buttons are marked in Chinese, the direction of entering and exiting the board, and the mechanical damage icon is marked.

8. There is a transparent window on the equipment safety door, equipped with lighting lamps.

9. The equipment PLC opens the MES port to support data transmission.

|

Parts List |

|

|

Motor |

Rizo |

|

guide |

Shanghai Bank |

|

power supply |

Mingwei |

|

Plc |

Mitsubishi |

|

Display screen |

Mitsubishi |

|

blade |

Imported high-speed steel |

|

Gasket |

45 steel |

|

sensor |

Daochuan |

|

Three-color light |

Owen |

1. Efficient splitting, extremely labor saving, daily output can reach more than 100,000 pcs.

2. Fully automatic production can be realized by connecting the boarding equipment.

3. The degree of deformation of the sub-board is perfectly controlled, which conforms to the copper lamp board or COB board with intermittent products.

4. Simple training can be mastered and used; knife adjustment is not complicated, and ordinary employees can learn it after simple training.

5. Safety: door opening protection device to ensure safe production.

6. Unique new tool, the durability is relatively increased by 1.5-2 times.

Blade material: imported high-speed steel

The minimum distance between the knife and the knife is 3mm, and the knife edge thickness is 0.2mm

The size of the meson is customized according to the size of the PCB board

Note: The service life of the blade is 100,000 times, and it can be re-ground and reused. The blade depends on the situation, and it can be re-ground 2-3 times.

Features:

1. High positioning accuracy.

2. The cutting board stress is small.

3. Door opening protection device, high safety performance.

4. Automatic board feeding and cutting, higher efficiency.

5. It can be connected to the upper and lower board machines, saving labor.

1. Track feeding or board loading machine feeding, circuit board induction designated switch.

2. The sub-board machine will start to run. If the circuit board is not in the specified correct position, the machine will alarm and stop running, and manual correction is required.

3. After the plate is in place, the cylinder lifts and pushes the plate.

4. The cutting tool of the board splitter starts to run, and the product is cut by multiple groups of tools at the same time, and the whole board is divided at one time.

5. The product conveyor belt starts to run. After the product is divided, the conveyor belt stops immediately to ensure that the product stays on the conveyor belt, and the finished product is taken away manually or by a robot.

6. The machine completes a work process.

|

project |

HN-530 |

|

name |

Three-group multi-group multi-knife splitting machine |

|

Dimensions L/W/H |

1662mm×580mm×1060mm |

|

Tool size |

Round knife ϕ80mm×ϕ35mm×3mm |

|

Tool material |

Imported high-quality high-speed steel |

|

Tool brand |

Huanuo |

|

Sub-board thickness |

0.5-3mm board thickness (V-CUT depth, 1/3 of board thickness) |

|

Sub-board length |

50mm-1200mm |

|

Splitting speed |

300mm-500mm/s (speed adjustable motor, adjustable speed) |

|

Sub-board width |

50mm-300mm |

|

Operating Voltage |

220V/110V optional |

|

equipment power |

200W |

|

Total Weight |

About 380kg |

1. Commitment: Warranty period: 1 year, lifetime maintenance. Response time: After receiving the user's notice, professional and technical personnel will not exceed 24 hours (local) and 48 hours (off-site) on-site service to ensure 24-hour uninterrupted after-sales technical service support; repair time: 48 hours.

2. Free warranty: Free warranty during the warranty period, and after the warranty period, spare parts and maintenance services are guaranteed at a reasonable price.

3. Free training: On the day of training, the purchaser’s technical personnel will be trained on the equipment operation for free to ensure that the user’s personnel can be proficient in conventional use methods such as various equipment and software, as well as the judgment and resolution of minor faults.

简体中文

简体中文 English

English Contact us

Contact us